Get Free Sample

Mainly composed of super absorbent polymer (SAP), SOCO®Polymer is a new type of functional material that can absorb a large amount of water and swell into hydrogel. It is a synthetic resin that can not only absorb water but also hold water from releasing (under certain pressure). SOCO®Polymer can generally absorb water equivalent to hundreds or even thousands times of their volume. It is widely used in industry, medical care, agriculture and other fields. Nowadays it has been the more popular choice of raw materials for manufacturing Ice Packs.

SOCO® Polymer 1

SOCO® Polymer is special for dry ice packs, gel icepack, icepack sheet etc.. It has better capabilities of water absorption and water-keeping. The ice pack made of SOCO® Polymer has a larger cold storage capacity. In addition, SOCO® Polymer is non-toxic and eco-friendly.

Product Characteristics

| Appearance | White Particles | Particle Size | Customizable |

| CAS No. | 9003-04-7 | Shelf Life | More Than 1 Year |

| Safety | Harmless No-Flammable | ||

| Application | Sodium Polyacrylate for Ice Packing | ||

| Certificate | ISO9001, SGS (non-toxic and harmless), SGS (no heavy metal residue), BV (degradable), REACH (SAPS with the lowest sulfate residue), etc. | ||

*For more details and information,please consult our specialists

SOCO® Polymer 2

SOCO® Polymer is the new upgraded version of products for dry ice packs, gel icepack, icepack sheet. It has more excellent performance like longer holdover time, better water absorption capacity, faster water absorbing speed, etc. The ice packs made from it can be suitable for more different applications, which help you improve the service efficiency of ice packs sheet, gel icepack and save cost.

| Appearance | White Particles | Particle Size | Customizable |

| CAS No. | 9003-04-7 | Shelf Life | More Than 1 Year |

| Safety | Harmless No-Flammable | ||

| Application | Sodium Polyacrylate for Ice Packing | ||

| Certificate | ISO9001, SGS (non-toxic and harmless), SGS (no heavy metal residue), BV (degradable), REACH (SAPS with the lowest sulfate residue), etc. | ||

*For more details and information,please consult our specialists

The Advantages of SOCO® Polymer

✔️Cooling for 24h

Efficient and stable

✔️Save Cost

Reusable products with less dosage

✔️Non-toxic & Harmless

Eco-friendly

25s

Faster Water Absorption Speed

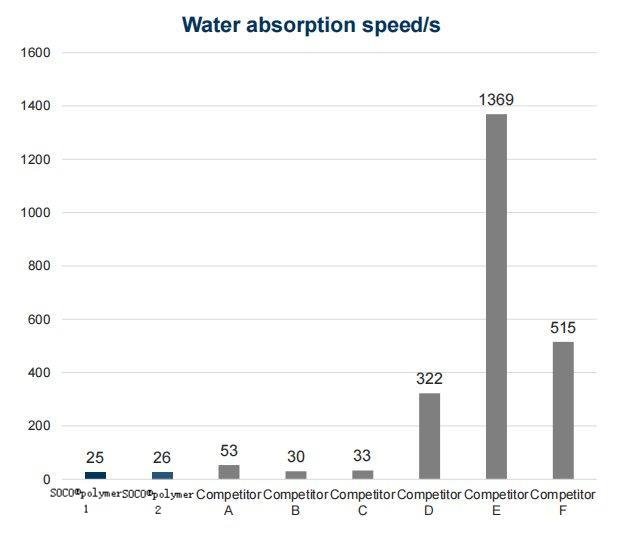

Through the comparison test of water absorption speed among and other similar products, with the same and equal water amount, SOCO® Polymer takes 25s to absorb water and expand into hydrogel, which is the shortest among all products.

*The data provided is for reference only, and there may be varying degrees of error in different objective environments. Please refer to actual usage for accuracy.

441times

441times

Stronger Water Absorbency

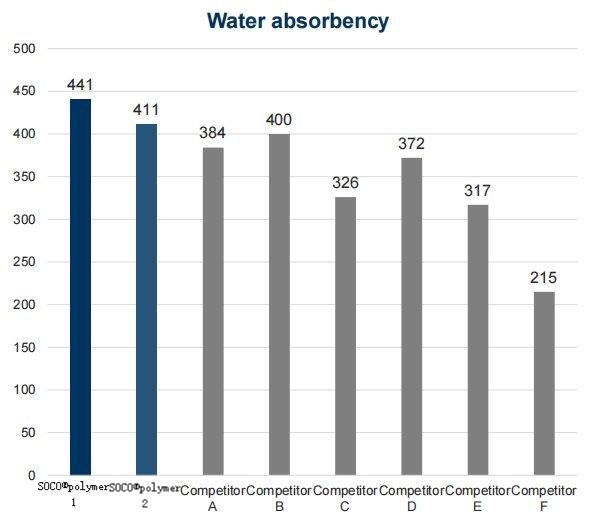

Through the comparison test of water absorbency speed among SOCO® Polymer and other similar products, with the same amount of products, SOCO® Polymer can absorb 441 times of its own volume, which is the highest among all products.

*The data provided is for reference only, and there may be varying degrees of error in different objective environments. Please refer to actual usage for accuracy.

1.12%

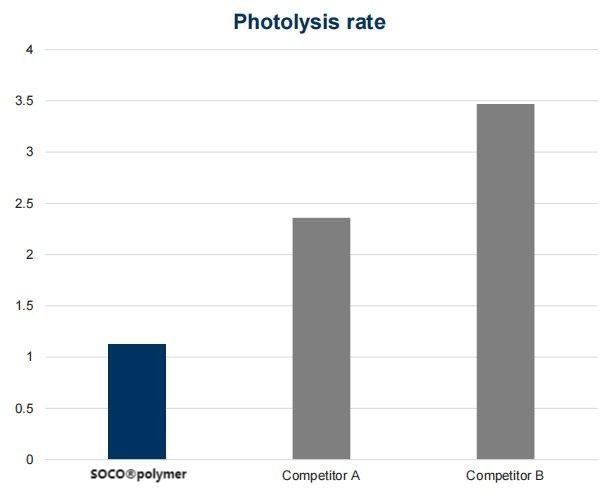

Lower Photolysis

We conducted a test to simulate the photodegradation levels of SOCO® Polymer and other products under natural lighting conditions within a month. The results showed that SOCO® Polymer had the lowest level of photodegradation, at only 1.12%. Competitor A had twice the level of photodegradation compared to SOCO® Polymer, while competitor B had three times the level. This indicates that SOCO® Polymer has a strong resistance to photodegradation and possesses stronger gel strength and water retention capabilities.

*The data provided is for reference only, and there may be varying degrees of error in different objective environments. Please refer to actual usage for accuracy.

>30h

>30h

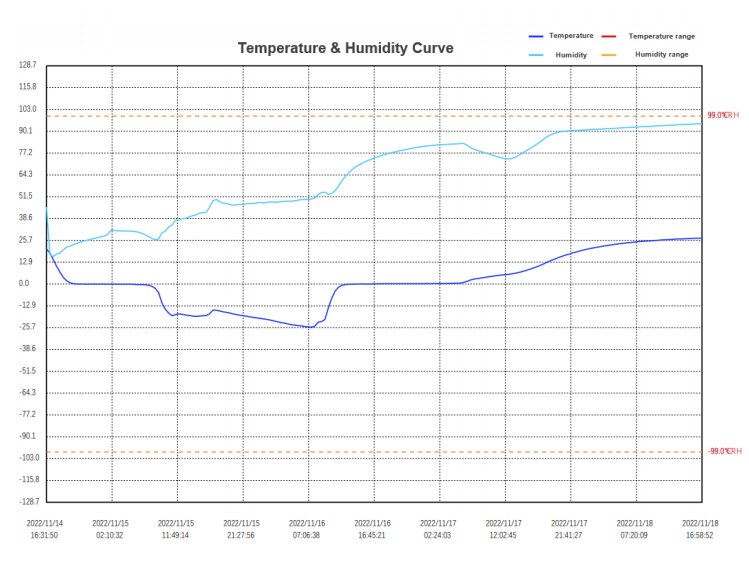

Longer Cooling Time

We’ve designed a test to observe the change of temperature of SOCO® Polymer, the result is very promising. SOCO® Polymer can maintain the cooling condition for up to 32.17h, which is much longer than other similar products.

*The data provided is for reference only, and there may be varying degrees of error in different objective environments. Please refer to actual usage for accuracy.

Finished Ice Packs

Made of SOCO® Polymer

Besides the raw materials (SOCO® Polymer)for dry icepacks, SOCO® also produces finished ice pack products, such as icepack sheet, dry icepack, reusable ice packs bulk, water filled ice pack and other commercial ice packs to name but a few, which are widely used in the field of medical, cold chain transportation, food fresh keeping, etc.

01Water Injection Ice Pack

Put SOCO® Polymer into packaging and pour tap water in a certain proportion, wait 3-5min to form gel. After that you can seal it and put it into refrigerator for 6 hours. Then it can be used.

02Self-priming Type Ice Pack

It is also called PE film+ Non-woven Ice Pack. Put SOCO® Polymer into ice pack bags and seal it. Then put it into water for swelling reaction for 3-5min, when take it out, put it into refrigerator with non-woven fabrics face up for more than 6 hours, then it can be used.

03Gel Ice Pack

Put SOCO® Polymer into water. When the gel forming is done, you can fill it into the packing and seal it. Put it into refrigerator for 6 hours before using.

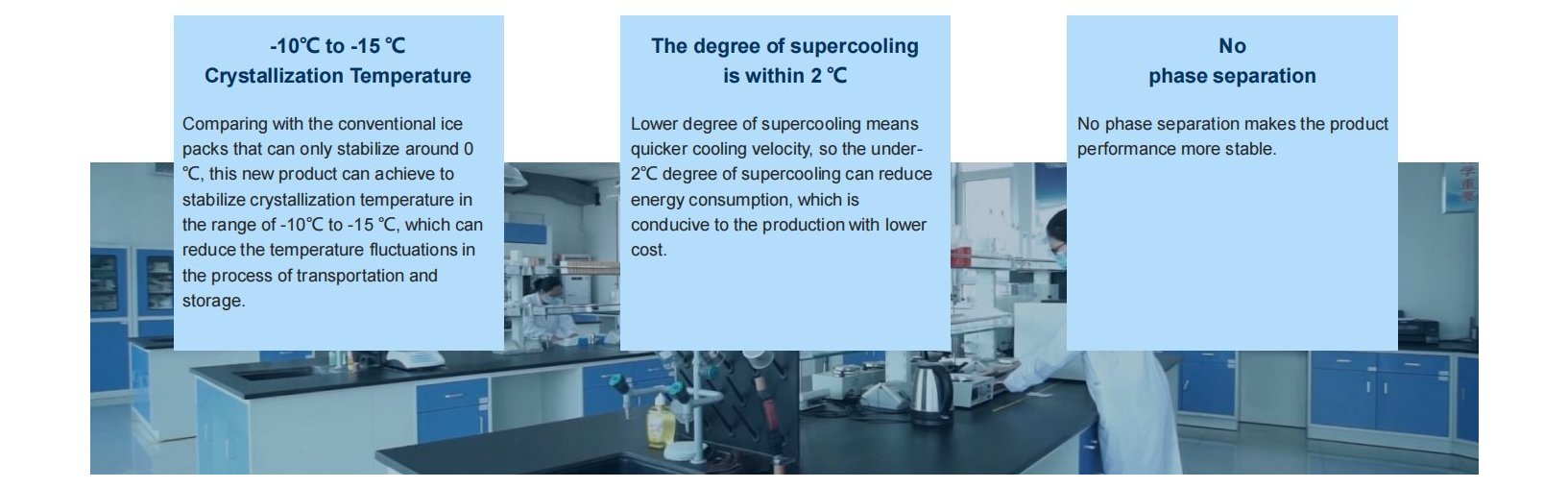

-10~-15 ℃ Ice Packs

The new product for -10~-15℃ Dry Ice Pack is one of the new projects of SOCO® that is being researched and developed.

It has more prominent superiorities and wider applicability.

We have “Ask The Expert” online service 24/7. If you have any questions please contact us.